Engineering an On-Demand 3D Drug Delivery System by Additive Manufacturing

This project is in Seed Phase lasting 6 to 9 month.

A central topic in the field of therapeutic medicine is the development of personalized drug delivery systems, which aim at customizing healthcare products to each individual patient.

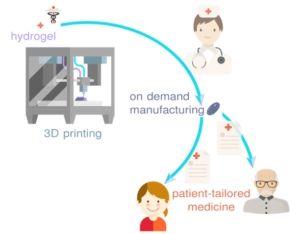

The idea is that, with such a customized approach, a better drug distribution and absorption is achieved, which results in an improvement of the treatment efficiencies and a reduction of undesired side-effects. Additive manufacturing (or 3D printing) opens up the possibility to make tailor-made medicine possible by creating drug formulations locally in the pharmacy and only when needed, i.e. on demand.

Such a novel approach will allow for flexibly reacting to different kinds of challenging environmental factors as e.g. happening during the current corona crisis. A key challenge in most current drug delivery systems is the lack of control over the release time, what can result in inefficient drug usage. One approach to expand the time frame during which active agents are delivered at therapeutic concentrations is to combine different drug encapsulation strategies, each of which possesses its own, typical release kinetics.

We will explore the possibility to apply 3D-printing techniques to produce such an on-demand drug delivery system.

This system will be based on a (bio)polymer-based hydrogel into which active molecules (= pharmaceuticals) will be embedded during the printing process. We will compare two strategies of how those drug molecules are incorporated: first, without a secondary encapsulation (i.e., by directly adding the drug molecules to the (bio)polymers); second, by encapsulating the drug molecules into nanoparticles created from biopolymers by electrospraying. We will assess the release efficiency of those two drug embedding strategies by spectroscopic methods thus identifying the most promising combination of printing parameters and drug encapsulation/embedding methods.

The idea is that, with such a customized approach, a better drug distribution and absorption is achieved, which results in an improvement of the treatment efficacies and a reduction of undesired side-effects.

#on-demand manufacturing #3Dprinting #drugdelivery #patient-tailored medicine

Modifying existing 3D printing strategies for applications in drug delivery opens unprecedented possibilities for personalized medicine.

3D printing will play a major role in the healthcare field in a near future by allowing a drug production on demand and directly on the delivery place.

Our goals

- Patient-tailored drug delivey systems: The objective of this project is to develop hydrogel-based drug delivery systems which can be shaped in a 3D printing process to realize patient-specific drug delivery on demand. Therefore, the hydrogel will serve as a carrier system into which one or multiple drugs can be individually embedded; when exposed to a liquid environment (e.g., a body fluid), those drugs will then be released over time.

- Therapeutic dosage control: By embedding the drug either as is, or encapsulated into a nanocarrier (which we will create from different biopolymers using an electrospraying approach), the release kinetics of the drugs from the printed hydrogel matrix will be adjusted. In addition to finding optimal process parameters for the hydrogel printing procedure, also establishing different biopolymer-based nanocarriers and assessing their suitability (in terms of reproducibility, particle size distribution, drug loading and release capacity) will be part of the project.

- On-demand manufacturing: Additive manufacturing (or 3D printing) opens up the possibility to make tailor-made medicine possible by creating drug formulations locally in the pharmacy and only when needed, i.e. on demand. In such a scenario, the drug formulation would be fully adapted to the person who will consume it; furthermore, such a novel approach will allow for flexibly reacting to different kinds of challenging environmental factors as e.g. happening during the current corona crisis; examples of such factors include shipment limitations of pills produced abroad resulting from the pandemic-induced closing of borders or shortage of pharmaceutical products that arise from the (transient) shut-down of industrial facilities that mass-produce pills.

Investigators

Prof. Dr. Oliver Lieleg

Carolin Rickert, M.Sc.