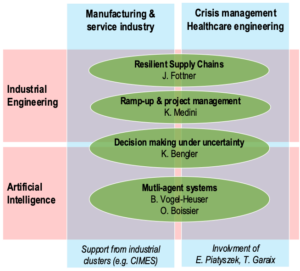

Decision support for ramp-up and ramp-down management – Evidences from manufacturing and crisis contexts

This is a seed phase project lasting from 6 up to 9 months.

The COVID-19 sanitary crisis uncovered the difficulty of manufacturing companies to timely respond to high-volume demands of specific products such as Personal Protective Equipment (EPI) and resuscitative equipment. Outsourcing has shown its limitations since the delocalized industry is not performing as expected within the current global crisis. Therefore, existing and innovative approaches need to be combined in order to foster production ramp-up management to meet demands at given territorial levels in times of crises.

The RAMP-UP project addresses these issues by developing methodological guidances, decision-aid methods, and tools for the flexible adaptation of production volumes and mixes within enterprises and enterprise networks while simultaneously assuring quality, efficiency, and resilience.

#AI #Crisis Management #RampUp

The COVID-19 crisis has shown us that new ramp-up management approaches are necessary that combine methods and best-practices from several disciplines to steer manufacturing companies through dynamic and uncertain times.

Our goals

- Define a ramp-up/ramp-down management approach applicable both at the local level of an enterprise and at the global level of the enterprise network to dynamically respond in times of high uncertainty;

- Provide guidance onhow to address sustainability objectives such as quality, resilience, agility, environmental impact, and change management during ramp-up;

- Define decision-aid tools to support local and global strategies for optimization in decentralized and dynamic environment;

- Address the management and representation of knowledge about stakeholders as well as sensed spatio-temporal and uncertain data (e.g., enterprise profiles, production capacity, product mix, etc.).

Investigators

Prof. Dr.-Ing. Birgit Vogel-Heuser

Prof. Dr.-Ing. Johannes Fottner

Prof. Dr. phil. Klaus Bengler

Investigators